- Home

- Corporate

- Solutions

- Division

- Gallery

- Client

- Blog

- Contact Us

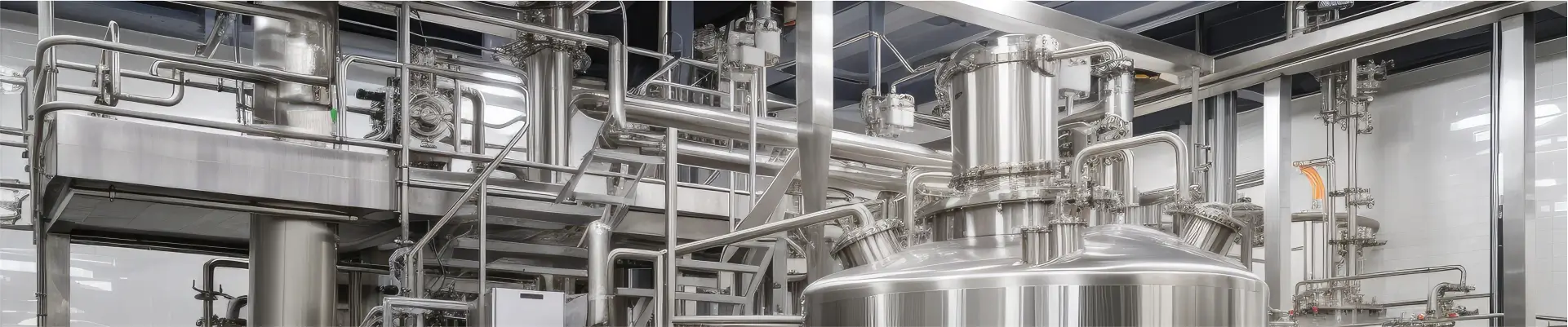

Toothpaste Manufacturing Plant

Toothpaste Manufacturing Plant Manufacturer in the USA

USA Pack Machines LLC offers an advanced Toothpaste Manufacturing Plant, engineered to meet the diverse demands of the oral care industry. With production capacities ranging from 100 kg to 5000 kg, this plant ensures efficient formulation and processing of toothpaste with consistent quality in every batch. It integrates cutting-edge mixing, homogenization, and vacuum deaeration technologies to deliver smooth, uniform, and high-quality toothpaste.

The system features a closed-loop, hygienic design that minimizes contamination risks, ensuring a safe and controlled production environment. With advanced automation, the plant reduces manual intervention, boosts efficiency, and allows precise control over critical parameters such as temperature, viscosity, and mixing speed. This makes it ideal for producing everything from fluoride toothpaste to specialized variants like whitening or sensitive-teeth formulations.

Toothpaste Processing Plant Manufacturer in the USA

Designed for versatility and scalability, our plant supports both small-scale startups and large-scale production facilities. Built with durable stainless steel construction and a modular design, it offers long-term reliability and easy customization to adapt to future market needs.

The Toothpaste Processing Plant by USA Pack Machines LLC combines competitive pricing with premium features such as automated controls, stainless steel vessels, and vacuum deaeration. Its robust engineering ensures smooth, efficient, and hygienic operations, making it a smart investment for manufacturers of all sizes.

Available capacity – 100 kg to 5000 kg

| # | Model | Capacity |

| 1 | UPML-OMP | 100 KG to 5000 KG |

- All contact parts are of SS 316 quality material & finished to class 4B (Mirror) finish and are service free

- Easily Cleanable

- Complete lid lifting arrangement to facilities cleaning at the time of product change over

- Specially designed becomixs stirrer with flexible Teflon scrapers

- All transfers are done through vacuum to avoid any hand touch & contamination

- The entry of all agitators is from top & High-Speed Emulsifier from bottom or In-line Emulsifier (as per customer choice)

- All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized

- All pipes, interconnecting piping, and valves are of SS 304 / SS 316 (as per customer requirement) seamless quality, internally electro-polished, with tri-clover ended joints

- All values of temperature & time of the plant are indicated digitally on the control panel.

- All the inlet & outlet connections are provided with tri clover joints, which are very easy for cleaning & replacement.

- Manufacturing Vessel

- Wax Phase Vessel

- Water Heating Vessel

- Storage Vessel

- Ointment Transfer Pump (Lobe Pump)

- Ointment Transfer Pump (Metering Pump)

- Control Panel

- Piping of Complete Plant

- Working Platform

- Vacuum Pump

- Steam / Electrically Operated

- Load Cell for Accurate Weighing

- PLC Based Control Panel for Process Automation

- Utility Piping Under Working Platform

Products

Products