- Home

- Corporate

- Solutions

- Division

- Gallery

- Client

- Blog

- Contact Us

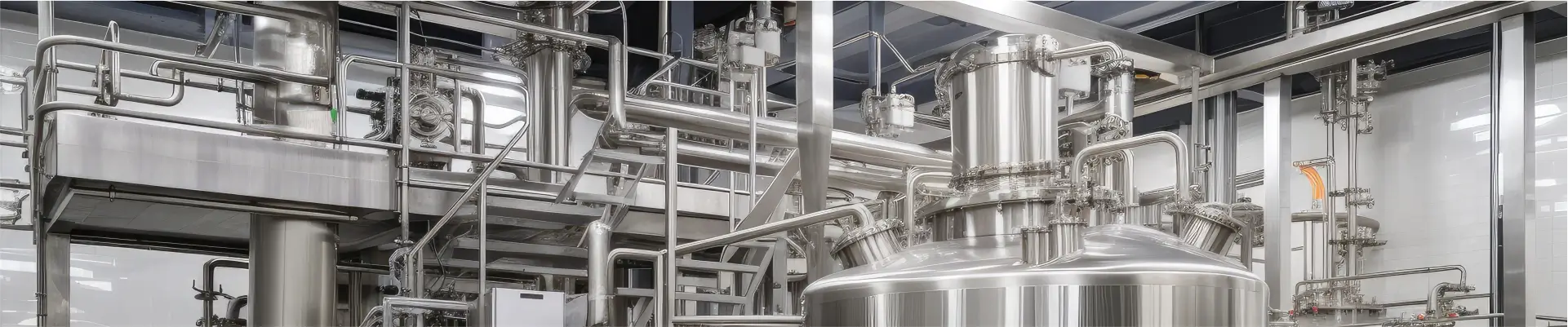

Shampoo Manufacturing Plant

Shampoo Manufacturing Plant Manufacturer in the USA

USA Pack Machines LLC offers a state-of-the-art Shampoo Manufacturing Plant, designed to meet the evolving needs of personal care product manufacturers. With capacities ranging from 100 kg to 5000 kg, our plant ensures efficient, precise, and consistent formulation of shampoos and other liquid-based products.

Our Shampoo Processing Plant integrates advanced technology for controlled mixing, emulsification, and homogenization, delivering uniform product quality in every batch. Built with stainless steel construction and a closed-loop design, the system ensures durability, hygiene, and minimal contamination risks—meeting the highest industry standards.

With automation options that reduce manual intervention, our plant enhances production efficiency, lowers operational costs, and scales seamlessly from small to large batch production. Whether you’re producing hair shampoos, body washes, or specialty liquid formulations, USA Pack Machines LLC provides the precision, flexibility, and reliability you need to stay competitive.

Our Shampoo Manufacturing Plant is also designed for easy customization, giving you the ability to adapt quickly to diverse formulations and market demands. Equipped with automated control systems, stainless steel tanks, and precision mixers, it offers excellent value—combining premium features with competitive pricing.

Available Capacities: 100 kg to 5000 kg

Industries Served: Personal Care, Cosmetics, Pharma & More

USA Pack Machines LLC stands as a trusted Shampoo Processing Plant Manufacturer & Exporter in Morrisville, North Carolina, USA, delivering world-class solutions tailored to your production needs.

| # | Model | Capacity |

| 1 | UPML-OMP | 100 KG to 5000 KG |

- All contact parts are of SS 316 quality material & finished to class 4B (Mirror) finish and are service free

- Easily Cleanable

- Complete lid lifting arrangement to facilities cleaning at the time of product change over

- Specially designed becomixs stirrer with flexible Teflon scrapers

- All transfers are done through vacuum to avoid any hand touch & contamination

- The entry of all agitators is from top & High-Speed Emulsifier from bottom or In-line Emulsifier (as per customer choice)

- All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized

- All pipes, interconnecting piping, and valves are of SS 304 / SS 316 (as per customer requirement) seamless quality, internally electro-polished, with tri-clover ended joints

- All values of temperature & time of the plant are indicated digitally on the control panel.

- All the inlet & outlet connections are provided with tri clover joints, which are very easy for cleaning & replacement.

- Manufacturing Vessel

- Wax Phase Vessel

- Water Heating Vessel

- Storage Vessel

- Ointment Transfer Pump (Lobe Pump)

- Ointment Transfer Pump (Metering Pump)

- Control Panel

- Piping of Complete Plant

- Working Platform

- Vacuum Pump

- Steam / Electrically Operated

- Load Cell for Accurate Weighing

- PLC Based Control Panel for Process Automation

- Utility Piping Under Working Platform

Products

Products