- Home

- Corporate

- Solutions

- Division

- Gallery

- Client

- Blog

- Contact Us

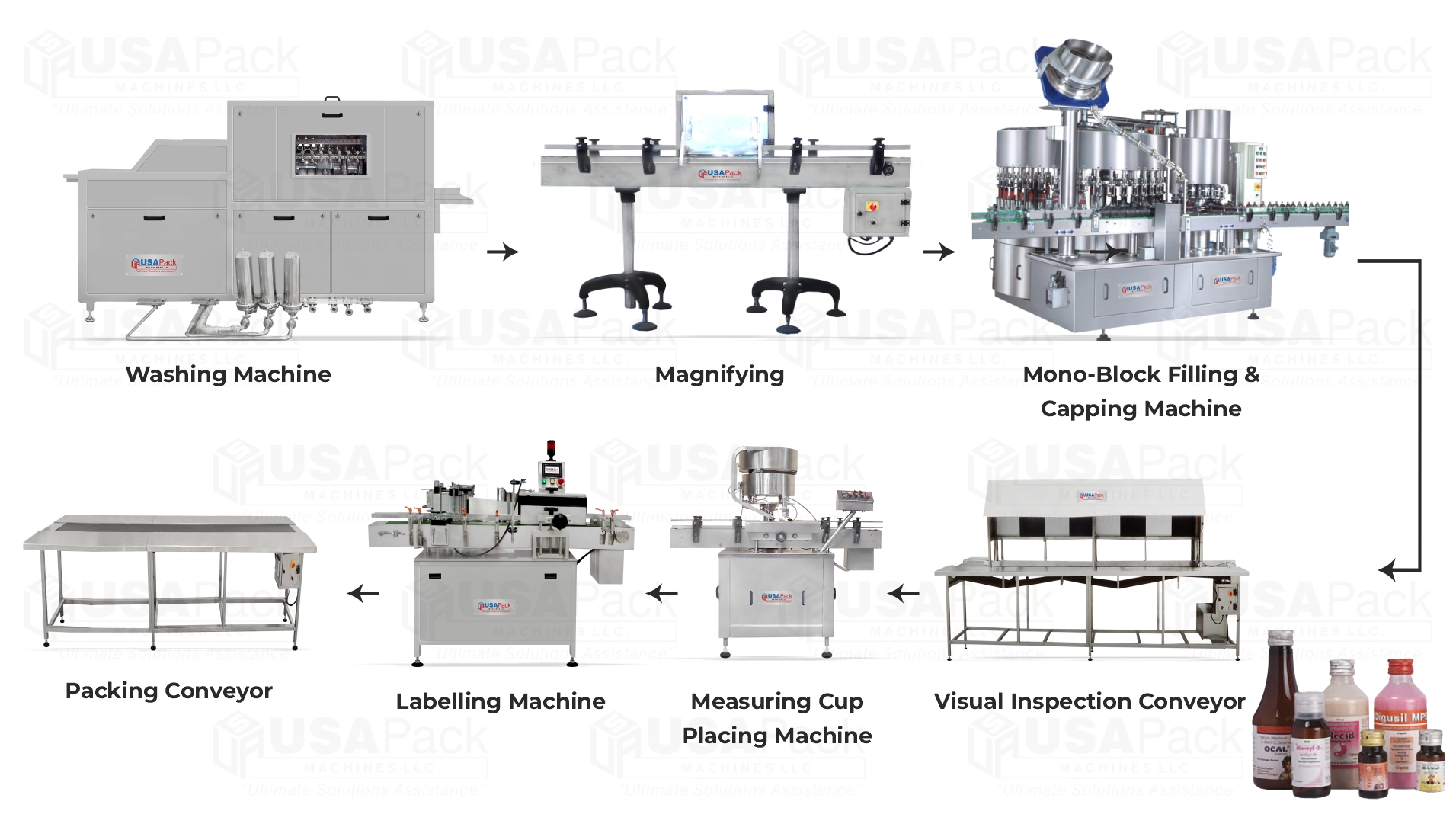

Automatic Monoblock Liquid Oral Syrup Packaging Line

Automatic Monoblock Liquid Oral Syrup Packaging Line for Oral Liquids, Syrups and Suspensions

USA Pack Machines LLC offers a state-of-the-art Automatic Monoblock Liquid Oral Syrup Packaging Line designed for oral liquids, syrups, and suspensions. This advanced solution handles bottles ranging from 10 ml to 1000 ml with output speeds of up to 300 bottles per minute, ensuring precision, consistency, and high efficiency.

Complete Liquid Packaging Line Manufacturer in the USA

Welcome to our comprehensive liquid packaging solutions tailored for the pharmaceutical and healthcare industry. USA Pack Machines LLC delivers an end-to-end, fully automated solution for filling, capping, and labelling oral liquid, syrup, and suspension bottles, ensuring quality and compliance with global industry standards.

Our commitment to excellence has positioned us as a trusted partner for pharmaceutical businesses seeking cutting-edge, reliable, and efficient packaging technology. With unparalleled efficiency, precision engineering, and robust performance, our systems help you elevate your production process and maintain consistent quality.

USA Pack Machines LLC specializes in delivering complete liquid processing and packaging solutions for the pharmaceutical industry. Our advanced systems are designed to handle oral liquids, syrups, suspensions, and other pharmaceutical formulations with precision, efficiency, and compliance. From filling and capping to labelling and secondary packaging, we provide end-to-end solutions that meet stringent regulatory requirements and ensure product integrity.

Our talented engineering team stays ahead of market trends and delivers innovative solutions customized to your specific requirements. From filling to capping and labelling, every step of the process is designed for maximum efficiency and compliance with stringent hygiene and regulatory standards.

- Accurate Fillings

- Aseptic Packaging & Compliance

- Versatility

- High Speed & Efficiency

- Customization

- Bottle Washing Machine

- Magnifying Dome

- Mono-block Filling & Capping Machine

- Inspection Conveyor

- Measuring Cup Placing Machine

- Bottle Labelling Machine

- Automatic Syrup Bottle Cartoning Machine

| Sample Products | Brute, Pet, Amber – Bottles, Jars |

| Sample Product Size | 10 ml to 1000 ml |

| Types of Drugs | oral liquid, syrup and suspension |

| Output Speed | Up to 300 bottles per minute |

Bottle Washing Machine for Syrup Bottles

The Automatic Linear Bottle Washing Machine from USA Pack Machines LLC delivers fast, hygienic cleaning for oral liquid, syrup, and suspension bottles. A rugged main frame carries the in-feed turntable, precision washing nozzles, and a smooth out-feed conveyor to keep production flowing without interruption. Integrated pumps with tanks, cartridge filter housings, pneumatic systems, motors, and gearboxes drive deep, consistent washing and dependable performance. A smart electrical panel with AC drive ensures accurate control, while optional PLC, HMI, and an SS cabinet with safety acrylic doors elevate automation, operator safety, and ease of use—supporting high-quality pharmaceutical packaging every shift.

Magnifying Glass Conveyor for Syrup Bottles

Magnifying Glass Conveyors deliver precise visual inspection for oral liquid, syrup, and suspension bottles by integrating high-clarity magnifying lenses into an in-line conveyor system. A robust structure supports a smooth product transmission belt with adjustable guides, along with a tube light, white inspection box, magnifying glass, AC drive, motor, and main ON/OFF control. As bottles move steadily along the conveyor, operators inspect fill levels, surface defects, and overall quality with enhanced visibility and confidence. USA Pack Machines LLC supplies this inspection conveyor as a standalone unit or seamlessly integrates it into running lines, with options for incomplete filling line automation to ensure consistent, dependable quality control.

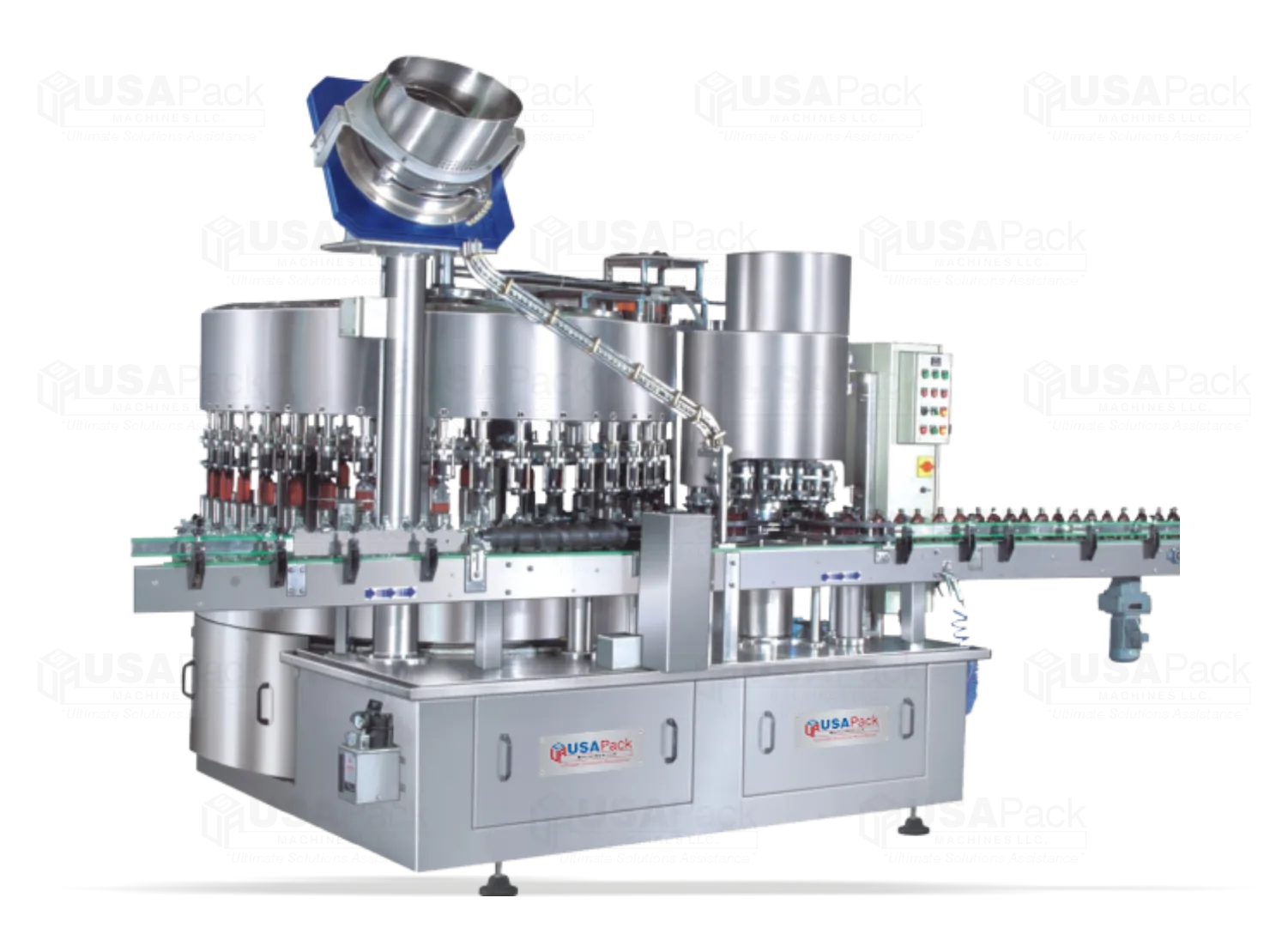

Monoblock Filling and Capping Machine for Syrup Bottles

The Monoblock Filling and Capping Machine from USA Pack Machines LLC delivers accurate filling and secure capping for oral liquid, syrup, and suspension bottles within one compact solution. It synchronizes filling and capping in a single flow to achieve precise dosing, leak-tight sealing, and smooth bottle movement at high operating speeds. Engineered for hygienic pharmaceutical production, the machine minimizes manual handling, optimizes floor space, and boosts overall line efficiency—while consistently delivering dependable performance and uniform quality for oral liquid and syrup packaging.

Visual Inspection Conveyor for Syrup Bottles

Syrup Bottle Measuring Cup Placing Machine

The Automatic Measuring Cup Placing Machine from USA Pack Machines LLC delivers precise and hygienic cup placement for oral liquid, syrup, and suspension bottles. A robust main structure carries a smooth product transmission belt with adjustable guides, supported by a cup bowl feeder, efficient delivery chute, and a precision pressing head for accurate placement. Simple bottle height adjustment, paired with a dependable motor and AC drive, ensures synchronized, high-speed operation. A centralized electrical panel allows easy control and monitoring, minimizes manual handling, boosts line efficiency, and delivers consistent, professional packaging results.

Syrup Bottle Labelling Machine

Packing Conveyor for Bottle Carton Packaging

Packing Conveyors from USA Pack Machines LLC ensure smooth and dependable transfer of oral liquid, syrup, and suspension bottles across a complete packaging line. A continuous, dynamic conveyor belt actively handles loading and unloading between machines, keeping bottles aligned and moving at a steady pace. By maintaining consistent flow, these conveyors reduce manual handling and significantly improve line efficiency. Widely adopted across global packaging operations, they support critical production stages, enable seamless machine-to-machine movement, and help maintain uniform output in oral liquid and syrup bottle packaging.

Products

Products