- Home

- Corporate

- Solutions

- Division

- Gallery

- Client

- Blog

- Contact Us

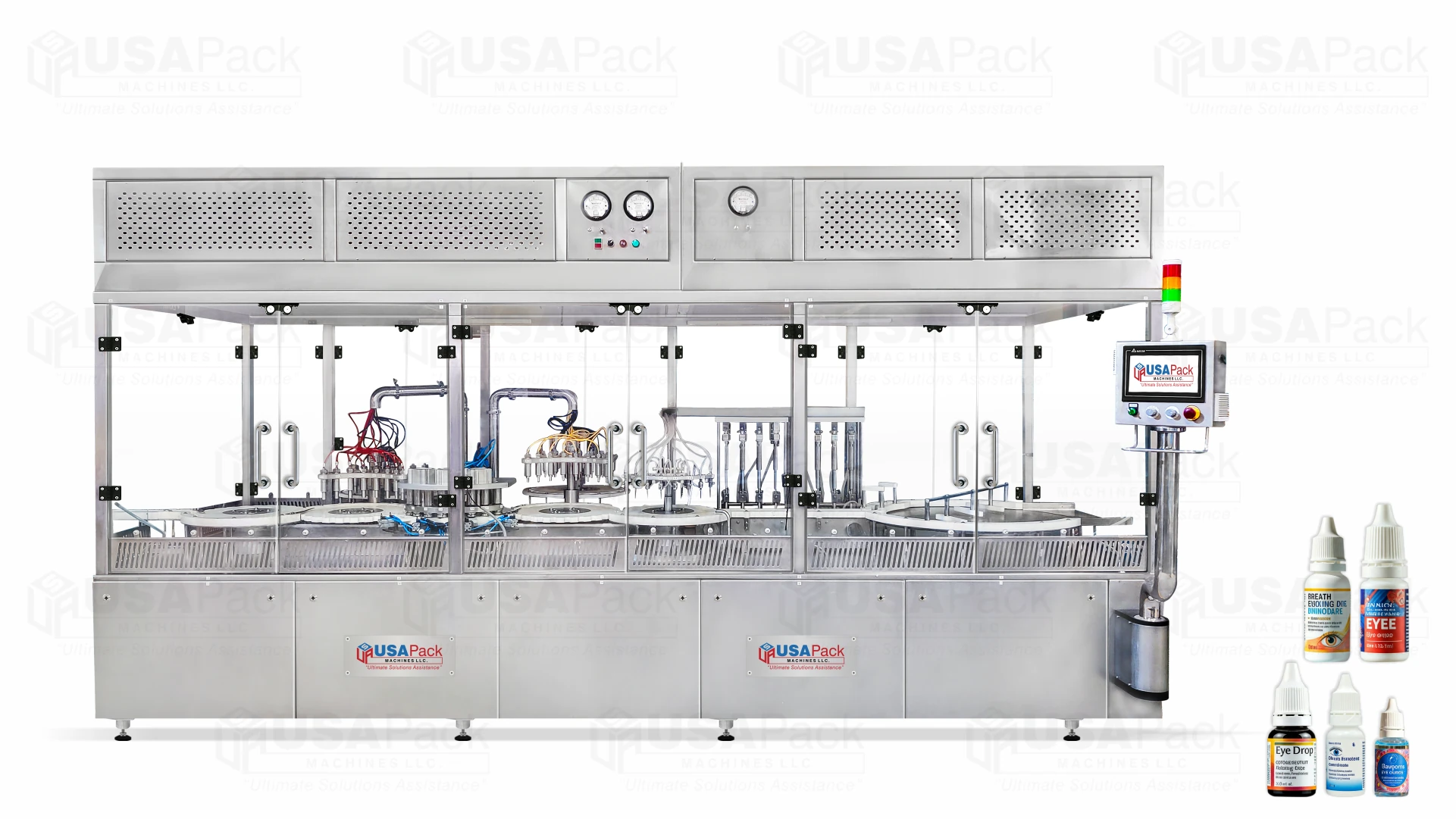

Automatic 3-Piece Eye/Ear Drop Filling, Plugging and Capping Machine

Automatic 3-Piece Eye/Ear Drop Filling, Plugging, and Capping Machine

The Automatic 3-Piece Eye/Ear Drop Filling, Plugging, and Capping Machine by USA Pack Machines LLC is a compact, versatile, and high-performance solution designed to meet the stringent demands of the pharmaceutical industry. Built with precision and engineered for efficiency, this machine integrates liquid filling, plug fitting, and screw capping into a seamless

process, ensuring speed, accuracy, and product integrity.

Crafted with a stainless-steel matt finish body, the unit is not only durable but also compliant with hygiene and GMP standards. It comes equipped with a stainless-steel slat conveyor, reciprocating nozzle with self-centering devices, and a robust stainless-steel syringe system for precise and consistent liquid dosing. These features enable smooth operation, reduce downtime, and guarantee a contamination-free process.

The machine is powered by a synchronized A.C. motor with variable A.C. frequency drive, ensuring reliable performance and across different production speeds. Designed with user-friendly controls, it allows operators to manage production with minimal effort while maintaining consistency and quality.

Key Features and Benefits

- Integrated Design: Combines filling, inner plug fitting, and screw capping in one unit.

- High Accuracy Filling: Reciprocating nozzle and SS syringe ensure consistent dosing with minimal wastage.

- Compact and Versatile: Occupies less floor space while supporting a wide range of eye/ear drop packaging applications.

- Durable Build: Stainless-steel matt finish body for long-lasting, hygienic performance.

- User-Friendly Operation: PLC and HMI options available for simplified control and monitoring.

- Reliable Drive System: A.C. motor with variable frequency drive ensures steady and adaptable operation

Applications

This machine is the perfect solution for pharmaceutical companies producing:

- Eye drop bottles

- Ear drop bottles

- Other small-volume liquid containers requiring plug fitting and screw capping

| # | Model | Output Speed |

| 1 | UPML-EED | Up to 200 bottles per minute |

- The Machine is Manufactured or Developed Accordance with GMP Standards.

- The SS Square Pipe Structure and Doors Of SS 304 with Machine Base Plate is MS Painted Cladded with SS 304.

- Rigid Vibration Free Construction for Trouble Free Performance.

- All Contact Parts SS 316 L and Non-Contact Parts are SS 304.

- Machine with Mechanical Un-scrambler which Feed Vials in Proper Orientation.

- Rotary Motion Advance Filling System Which Can Fill Precise Volume in Vials.

- Nitrogen Purging Facility (Pre Or Post) Can Be Provided As An (optional).

- Electromagnetic Vibrator Bowls with Chutes for Inner Plugs and Caps.

- Pick N Place Star Wheel for Inner Plug and Caps.

- Star Wheel And Guides For Filling, Inner Plugging, And Capping.

- There is a Special Feature Which is Useful To Suck The Filling Material From Storage Tank to Nozzle End Very Quickly.

- The Pharma/Food Grade Silicon Tubes Use For Filling Purpose.

- Co-eccentric Nozzles For Quick Filling Of Liquids.

- Filling Volume Set With Timing Of Individual Nozzle Through Touchscreen HMI.

- Pressure Vessel with Manifold (optional).

- No Vial No Fill System.

- Low Air Machine Stop Sensor.

- No Inner Plug On Vial Detection System.

- Door Interlocking System.

- PLC with Programming & 7” Colour Touch Screen HMI.

- All Faults Can Be Appearing On The HMI Which Can Attend Easily By Operator.

- The Pharma Grade Silicon Tubes Are Used For Filling & CIP/SIP.

- Machine Equipped With LAF for Clean Air Environment (optional).

- Different Heights Of Vials, The Whole Assembly Of Inner Plug And Capping Can Be Moved Upwards & Downwards For Easy Changeover.

- User-Friendly and Very Less Maintenance Required.

- Most Reliable & Proven Components such as Pneumatics & Electrical/Electronic such as AC Motor, AC Drives, PLC & HMI Touchscreen, Switches, Sensors, MCB’s & Relay “CE” certified.

- 21 CFR System for Filling Machine

- Swing Conveyor Belt

- Toughen Glass Cabinet with SS Pipe Structure

- Laminar Air Flow Unit Up to Openable Door

- Buffer Vessel with Magnetic Stirrer AC VFD

| Product MOC | Eye and Ear Drop Bottles |

| Filling Material | Free Flow Liquid, Gel |

| Liquid Filling Volume | 5 ml to 15 ml |

| Output Speed | Up to 200 Products / Minute (Speed depends upon fill volume, viscosity of liquid Product neck & shape) |

Products

Products